In industrial production, there is a lot of waste. However, expanded metal solves the problem well. Because expanded metal is manufactured by slitting and stretching the metal sheet with a die creating different shaped holes in one step, which makes it more economical. Due to formed from a piece of metal, there are no welds or weak points, which make its structure more sounder than other type metals.

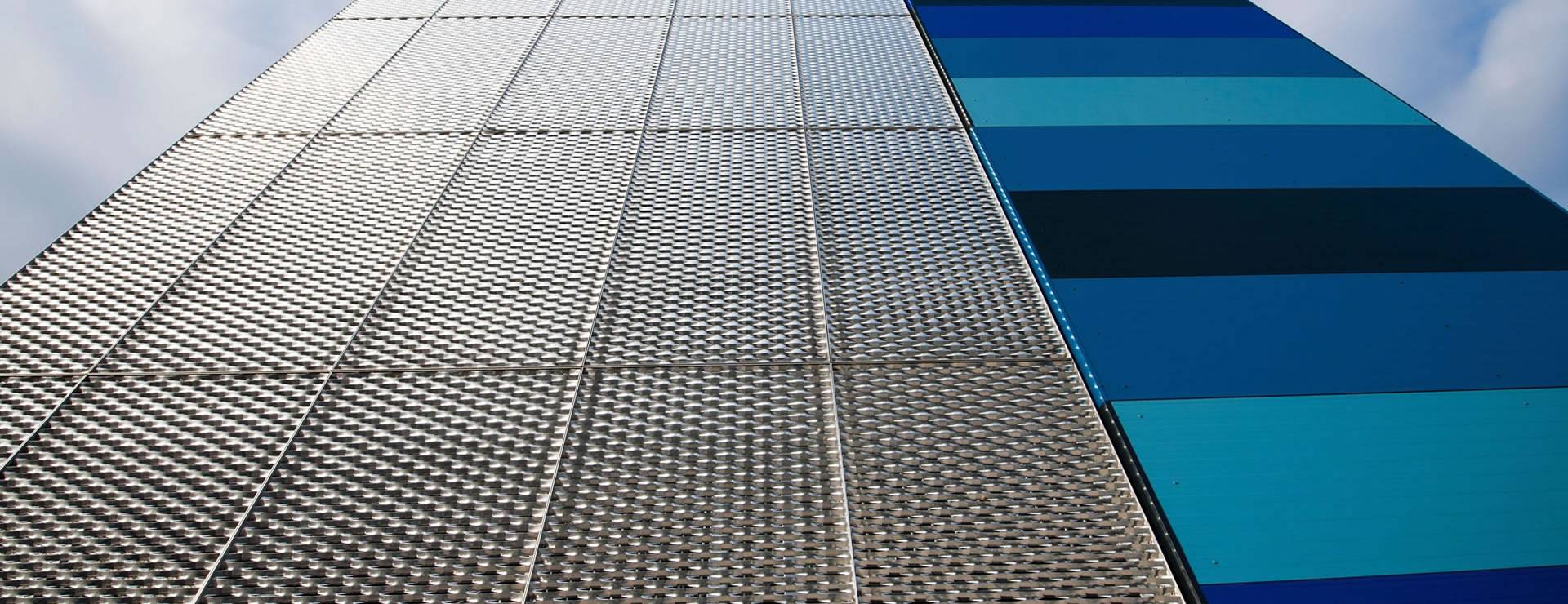

Raised expanded metal, also called standard expanded metal or regular expanded metal is a finished product as it comes from the press after having been die cut and expanded. Each sheet that comes off the expander is in standard or regular form with the junctions at the strands and bonds forming a ridge surface. The angles of the diamond strands allow maximum air circulation and distribute load on the metal to supporting frames. It with light weight and strength is an ideal for commercial and industry applications, such as storefront protectors, stairway, warehouse enclosures, lockers, etc.

Flattened expanded metal, undergoes an additional cold rolling process, creating a smoother surface and a finished product that is about 5% lighter than raised expanded metal. It with versatility is key to a virtually limitless variety of applications, such as, air and fluid filters, ventilation systems, partitions, speaker grills, machine and windows.